Torsion Springs

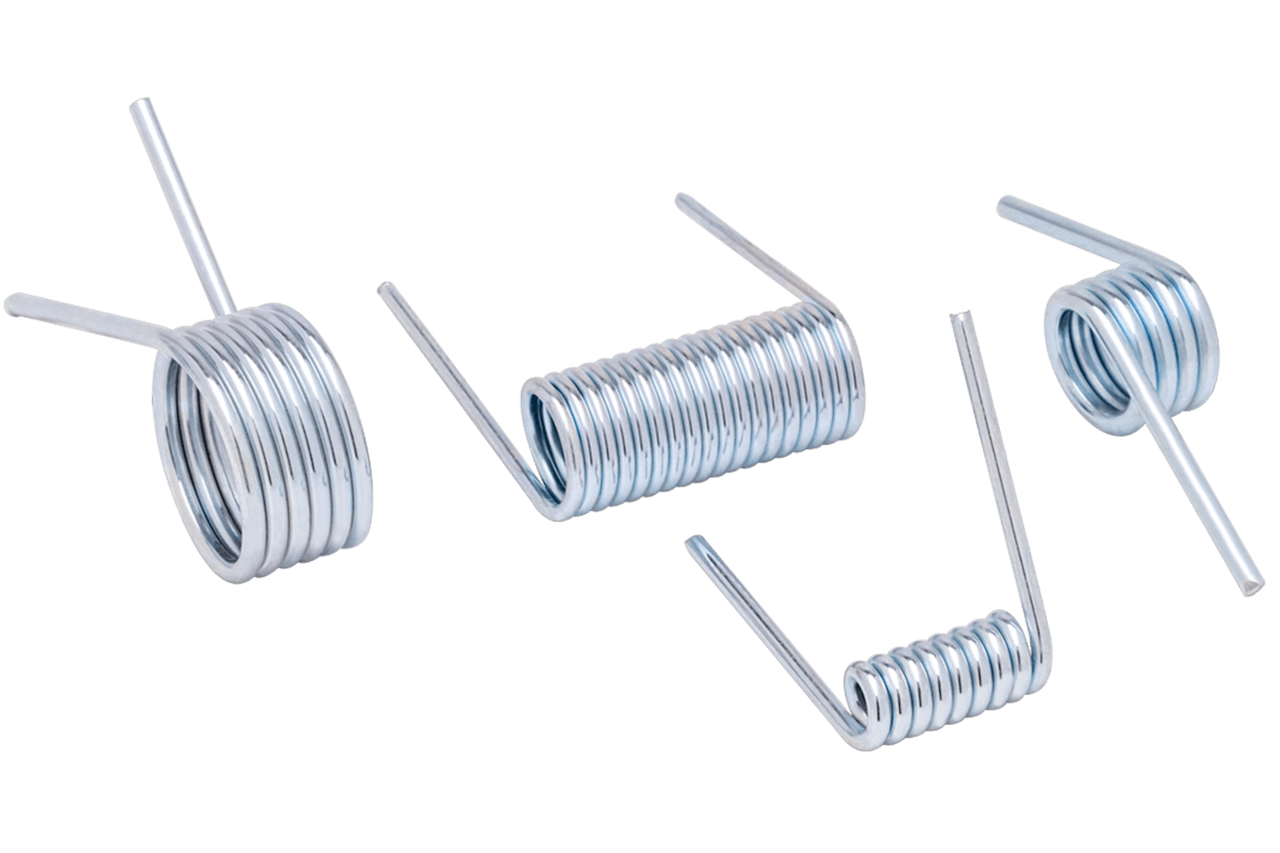

We offer custom and stock torsion springs, including industrial torsion springs, small torsion springs, and double-bodied torsion springs in multiple wire diameters for round or rectangular wire. We can also support virtually any bend type or orientation. Materials include steel, brass, bronze, and titanium, as well as specialty alloys. Stock springs often ship within 8 business hours of purchase, and we offer expert engineering support for custom spring requests.

In-Stock Torsion Springs

Browse our inventory of torsion springs for sale. We have hundreds of in-stock torsion spring designs that ship the same day. Click to filter results by material, diameter, and other parameters. Filter Results

The Highest Quality Standards

ISO9001

Certified for Quality Parts

AS9100D

Certified for Industry Needs

RoHS

Compliant for Peace of Mind

Quality Inspections

For Optimal Performance

TORSION SPRING MANUFACTURER

Custom Torsion Springs

Stock torsion springs not meeting your needs? Whatever your requirements, we’ll work with you to design and prototype a custom torsion spring to meet your exact specifications. MW Components teams are expert spring manufacturers. Our engineers can advise on optimum dimensions and winding together with materials, finishing, corrosion resistance, and production processes for industrial torsion springs and more. Get in touch with one of our experts to discuss your needs.

Torsion Spring Manufacturing

Materials

Brass and steel are the most common torsion spring materials. However, the alloy selected for wire production is determined by the application, weather, temperature and other environmental considerations. Don't see what you need? Contact us for a full list.

- Brass

- Carbon Steel

- Chrome Silicon & Vanadium

- Hastelloy®

- Inconel®

- Monel

- Phosphorous Bronze

- Stainless Steels

- Titanium

Finishes

We offer a range of finishing processes and industrial-grade finishes that help torsion springs resist corrosion and increase lifespan. We also provide packaging solutions to enhance product handling and workflow efficiency

- Black Oxide

- Electropolish

- Passivation

- Plating (Zinc, Nickel, Silver, & Tin)

- Powder Coating & Color Coding

- Zinc with Chromate

Wire Types

Our torsion springs can be made in a variety of wire diameters. Our production capabilities also support most bend types and orientations in the diameters below.

- Single-Bodied Torsion Springs: .008"-.625"

- Double-Bodied Torsion Springs: .008"-.236"

Shaped Wire Torsion Springs

Online, state-of-art CNC systems and other advanced machining capabilities enables us to design, prototype, and supply products in standard or shaped wire, including rectangular wire and square wire.

- Standard wire

- Rectangular wire

- Square wire

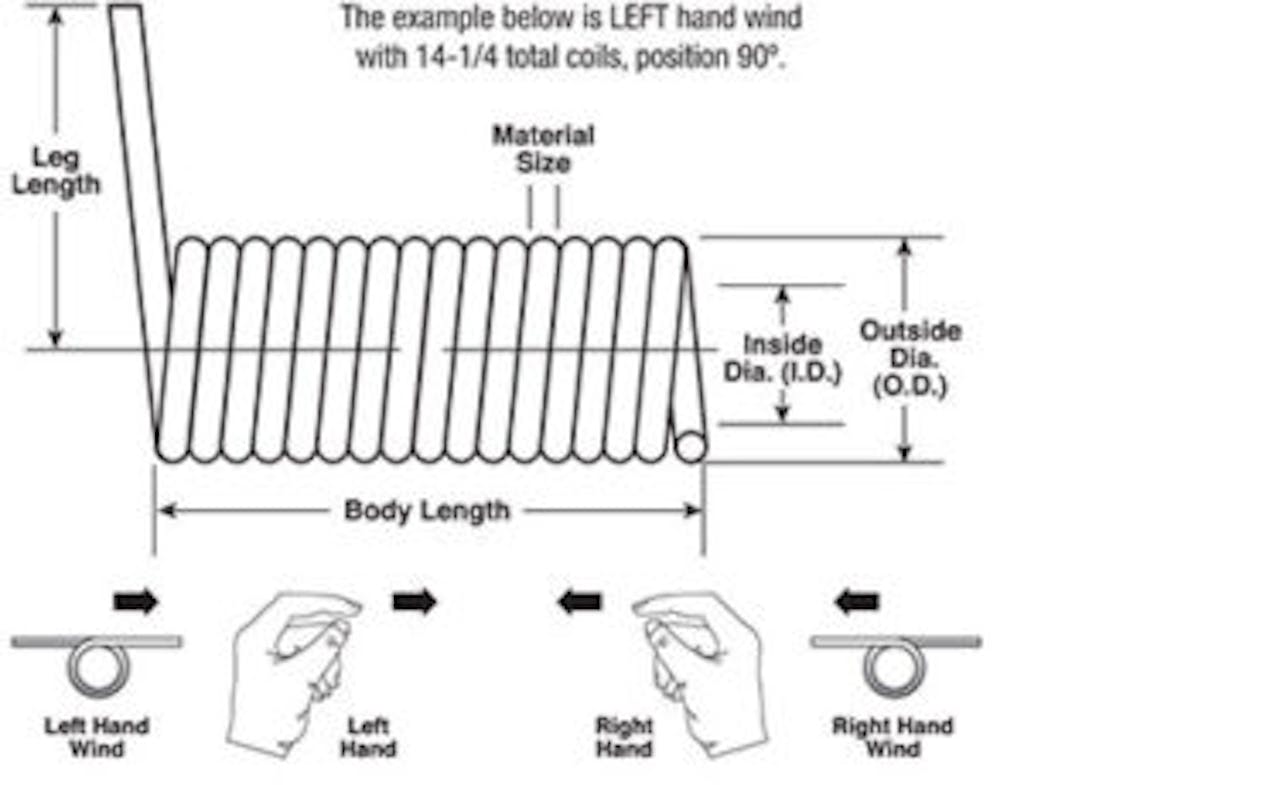

Torsion Spring Dimensions

Correct dimensions are crucial in identifying the right spring for your application. Use the steps and diagram below to measure accurately measure your torsion springs.

- Hold the spring in one hand, and the calipers in the other hand.

- Place the caliper “teeth” on the inside diameter. This is called the Inside Diameter (I.D.).

- Place the calipers on the “leg” to measure the wire. This is called Material Size (or Wire Diameter).

- Place the calipers on the working coils of the spring. This is called the Body Length. Place the calipers on the working coils of the spring. This is called the Body Length.

- Count the total coils, beginning at one end, just under where the leg leaves the body. Count to the other end, all full coils, and any fraction thereof. This is called the Number of Coils and determines leg position. i.e. 90°, 180°, etc.

- Determine the direction of the coil (Wind Direction). See diagram for hand/finger illustration. Right Hand Wind or Left Hand Wind.

About Torsion Springs

Overview

Torsion springs can store and release angular energy or statically hold a mechanism in place by deflecting the legs about the body centerline axis. They offer resistance to twist or rotationally applied force. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the preferred direction of the fabricated wind. Depending on the application, torsion springs can be designed to work in a clockwise or counter-clockwise rotation, thus determining the direction of the wind. Common torsion springs are those used in a clothes pin or a garage door.

MW offers a selection of stock and standard torsion springs with legs of equal length oriented at varying unloaded angles, as well as custom torsion spring manufacturing.

Torsion Springs Characteristics

The torsion spring configuration is created for the purpose of storing and releasing angular energy or for the purpose of statically holding a mechanism in place by deflecting the legs about the body centerline axis. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the preferred direction of the fabricated wind.

The direction of the fabricated wind can also be important for torsion spring applications due to the leg bearing/attachment location having to be on the left or right side upon assembly.

A torsion spring is normally supported by a rod (mandrel) that is coincident with the theoretical hingeline of the final product.

Typical Tolerances

Tolerance values for torsion springs depend on the body-diameter to wire-diameter ratio and are about +/- 10% in torque and +/- 5% in diameter.

Torsion Springs Featured Resources

Visit our resource center to see tips and tricks for how to design and engineer torsion springs and other MW Components parts.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.